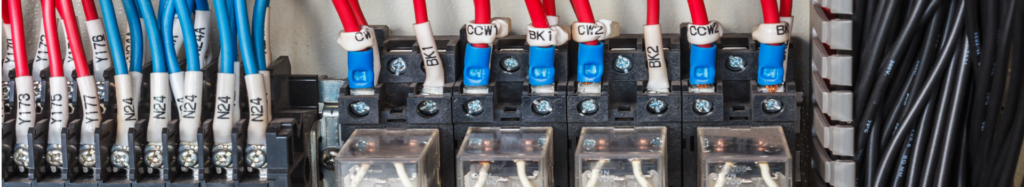

Our Box Build And Assembly Services

Our box build assembly services range from simple control boxes to more complex systems that form part of an engineered solution.

CAS are a build to print organisation (we do not design your product but we are specialists in producing it for you) so we work to your drawings and Bill-of-Materials.

However, our specialist team can advise on prototyping, one-off projects and design for manufacture (DfM).

Interested in receiving a quotation for your box assembly ? Fill in a few details on our RFQ Page and upload your drawings. We guarantee to respond within 1 working day !

What is Box Build Assembly ?

A box build includes all of the assembly work that is typically involved in an electromechanical assembly, but does not include the design and production of the printed circuit board (PCB).

The Box Build Assembly Process

The assembly process will vary from project to project and will typically include varying degrees of complexity at each step. A simple stage may be to place printed circuit board assembly (PCBA) into an enclosure. The following step may include the complex task of connecting a PCBA to a user interface display and uploading firmware or software to the device.

The most common box build assembly processes include installation of sub-assemblies, installation of other components, routing of cabling or wire harnesses, and fabrication of enclosures.

Common Assembly Services Provided By CAS

The following is a list of common box assembly tasks undertaken by CAS for our customers:

- wire preparation

- cable termination and assembly

- design and fabrication of enclosures

- electro-mechanical assembly

- system level assembly

- product assembly

- sub-level product assembly

- product packaging

- product labeling

- product testing

- software and firmware installation

- product configuration

Providing CAS (the electronics contract manufacturer) with all of the detail involved in a complete product assembly can help us model an assembly process to best serve our customers.